Location: Home/

Kaiyuan Plastic Industry/

Products/

Pipes and pipe fittings/

Modified polypropylene (MPP) power cable protection pipe

Location: Home/

Kaiyuan Plastic Industry/

Products/

Pipes and pipe fittings/

Modified polypropylene (MPP) power cable protection pipe

Modified polypropylene (MPP) power cable protection pipe is a type of power cable protection pipe made from modified polypropylene through extrusion molding processing. During construction, not only the traditional excavation and pipe laying method can be adopted, but also non-excavation pipe jacking or tensioning techniques can be used for operations. Compared with the traditional "trenching and pipe laying method", trenchless engineering is more in line with the current environmental protection requirements, eliminating the dust and traffic congestion and other disturbing factors caused by traditional excavation construction. This technology can completely lay pipelines in some areas where excavation operations cannot be carried out (such as urban center areas, cultural relic and historic site protection areas, crop protection areas, expressways, etc.)

Category: Modified polypropylene (MPP) power cable protection pipe

Key words:

Product Introduction

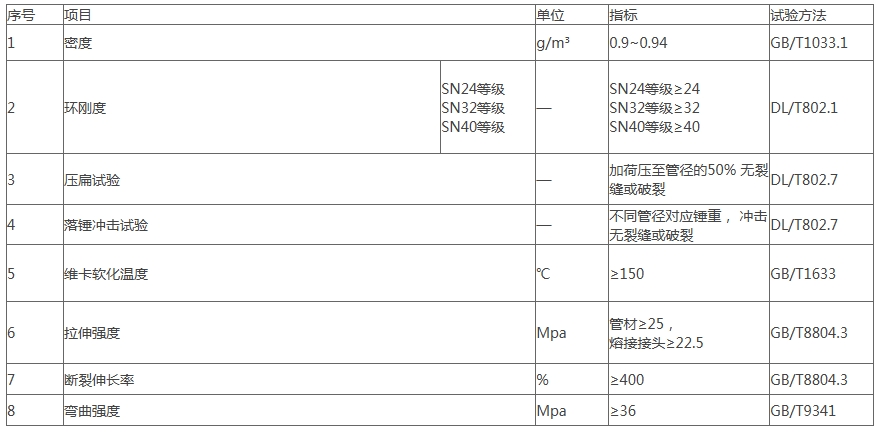

Modified polypropylene (MPP) power cable protection pipe is a type of power cable protection pipe made from modified polypropylene through extrusion molding processing. During construction, not only the traditional excavation and pipe laying method can be adopted, but also non-excavation pipe jacking or tensioning techniques can be used for operations. Compared with the traditional "trenching and pipe laying method", trenchless engineering is more in line with the current environmental protection requirements, eliminating the dust and traffic congestion and other disturbing factors caused by traditional excavation construction. This technology can fully be used to lay pipelines in areas where excavation operations cannot be carried out (such as urban central areas, cultural relic and historic site protection areas, crop protection areas, expressways, rivers and other special areas). The common diameters of MPP pipes range from ¢110 to ¢250mm, and they are divided into ordinary type and reinforced type. The common type is suitable for excavation laying construction and non-excavation crossing construction projects with a burial depth of less than 4 meters. The reinforced type is suitable for non-excavation crossing construction projects with a burial depth greater than 4 meters. The use of MPP power cable protection pipes for the laying of power cable pipelines has become a development trend in the industry.

Product performance characteristics

1. High strength: Under the action of external loads, it can be compressed to the direct half of the pipe without breaking, which can avoid damage caused by external pressure. When the pipe is deeply buried, it can eliminate the phenomenon of pipe deformation caused by soil pressure, fully ensuring the reliable operation of the internal cables

2. High heat distortion temperature: MPP power cable pipes, due to the use of modified polypropylene raw materials, have a Vicat heat resistance temperature of 12 °C and a long-term service temperature of -5 to 7 ° C. This effectively overcomes the limitation that pipes made of ordinary PE (polyethylene) can only be used below 40°C. It ensures that there will be no impact on the deformation of the pipe material due to local high temperatures generated by the power cable during operation or overload.

3. Excellent electrical insulation performance: MPP power cable pipes, like other plastic pipes, have good electrical insulation properties, with a large resistance coefficient, and can be used for the protection of high-voltage wires and cables above 30KV.

4. Convenient construction: It can not only be installed by the traditional method of slotting and pipe laying, but also by non-excavation towing, pulling and pipe jacking construction, reducing the damage to the original building caused by crossing Bridges, rivers, roads and railways, saving investment, shortening the construction period and minimizing the impact of the project on people's lives.

5. Smooth product: The inner wall of MPP pipes is smooth with low friction, which is conducive to the threading construction of power cables and reduces damage to the insulation protective layer of power cables.

The main uses of the product

1. Urban power grid construction and renovation

2. Urban municipal renovation projects

3. Construction of transportation roads and Bridges

4. Other trenchless horizontal directional drilling cable conduit projects