Location: Home/

Kaiyuan Plastic Industry/

Products/

Pipes and pipe fittings/

UPVC drainage and stormwater pipes and fittings

Location: Home/

Kaiyuan Plastic Industry/

Products/

Pipes and pipe fittings/

UPVC drainage and stormwater pipes and fittings

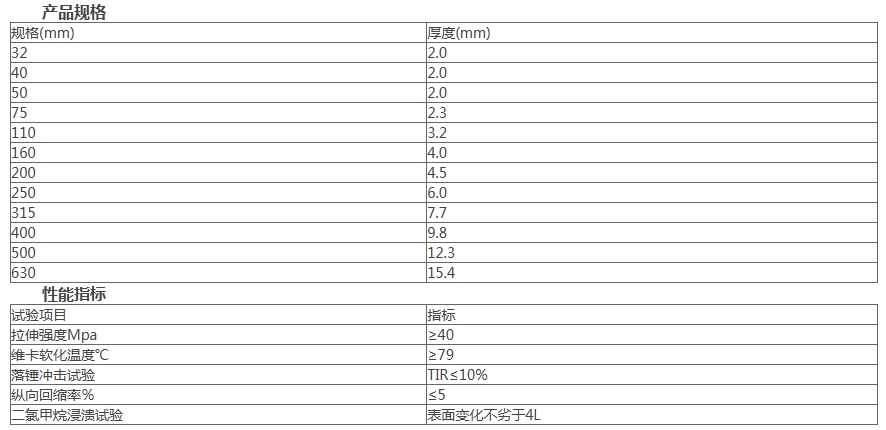

The PVC-U drainage pipes and fittings produced by Kaiyuan Company strictly comply with the national standards "Rigid Polyvinyl Chloride Pipes for Building Drainage" GB/T5836.1-2006 and "Rigid Polyvinyl Chloride Pipe Fittings for Building Drainage" GB/T5836.2-2006. Our company offers a complete range of building drainage pipes and fittings in various specifications, suitable for all kinds of building drainage projects. Our products are distributed throughout the country and Southeast Asia. In recent years, the company's R&D personnel have carefully summarized the application experiences in various regions and launched a batch of pipes and pipe fittings that are safer and more reliable to use, and more convenient, reasonable, economical and practical to install, such as H pipes and dn pipes with adjustable center distance calculation

Category: UPVC drainage, stormwater pipes and fittings

Key words:

The PVC-U drainage pipes and fittings produced by Kaiyuan Company strictly comply with the national standards "Rigid Polyvinyl Chloride Pipes for Building Drainage" GB/T5836.1-2006 and "Rigid Polyvinyl Chloride Pipe Fittings for Building Drainage" GB/T5836.2-2006.

Our company offers a complete range of building drainage pipes and fittings in various specifications, suitable for all kinds of building drainage projects. Our products are distributed throughout the country and Southeast Asia. In recent years, the company's R&D personnel have carefully summarized the application experiences of various regions and launched a batch of pipes and pipe fittings that are safer and more reliable to use, and more convenient, reasonable, economical and practical to install, such as H-pipes with adjustable center distance calculation, dn110 and dn160 reinforced 90° large-bend pipes with supports, and pipes and pipe fittings with adjustable coatings of various colors. Push the application technology of building drainage rigid polyvinyl chloride pipe systems to a new stage.Product performance characteristics

Excellent physical properties. Pipes and fittings produced with PVC are corrosion-resistant, have high impact strength and low fluid resistance (the flow rate is 30% higher than that of cast iron pipes of the same diameter). It is resistant to aging and has a long service life (according to the test data from the Ministry of Construction of the People's Republic of China, the service life is 40-50 years), making it an ideal material for building drainage and chemical wastewater discharge.

Lightweight, practical and easy to install. It weighs only 1/7 of cast iron pipes of the same diameter, which can greatly accelerate the project progress and reduce construction costs.

The inner wall is smooth, ensuring smooth drainage and preventing the pipe from getting clogged easily. The inspection port is uniquely designed, making the inspection operation convenient and requiring no tools at all.

Save construction costs. The comprehensive cost of using UPV pipes is lower than that of using cast iron pipes of the same specification, and the maintenance cost is also lower.

Application scope

It can be used for drainage inside and outside buildings or buried underground. After considering the chemical resistance and temperature resistance permitted by the material, it can also be used as a pipe for industrial sewage discharge.

Pipe bonding

Pipe socket connection should be strictly operated in accordance with the following procedures:

Before bonding and connecting, wipe the socket of the pipe and the socket of the pipe fitting clean.

② Measure the depth of the socket and make a mark at the pipe end.

③ Apply the adhesive first to the socket and then to the spigot. The coating should be uniform and in appropriate amounts.

④ Align with the direction and insert it into the marked area at one time, then rotate it by 1/4 turn.

⑤ Wipe off the remaining adhesive at the socket.

⑥ Let the bonded pipes stand until the joints are cured.

The safe use of adhesives should comply with the following regulations:

Adhesives and detergents should be used immediately upon opening. Non-operating personnel are not allowed to use them.

② There must be no open flame at the bonding point and the ventilation should be good.

③ Construction is not advisable below -10℃, and the bonding points must not be baked with fire.

④ Construction workers should be equipped with gloves. If the adhesive gets into the eyes by mistake, rinse immediately with plenty of clean water.

Installation Instructions

Pot tube and bevel:

The length of the sawn pipe is determined layer by layer based on the actual measurement and in combination with the dimensions of each connecting pipe fitting. For pipe sawing tools, it is advisable to choose fine-toothed saws, cutters and pipe cutters, etc. The fracture surface should be smooth and flat, and there should be no deformation at the cross-section. The socket part to be bonded can be filed with a medium-sized plate file to form a 15°-30° bevel. The bevel length is generally no less than 3mm, and the bevel thickness is preferably 1/3 to 1/2 of the pipe wall thickness. After the bevel is completed, the residual chips should be removed thoroughly.

Protection of socket interfaces

After the socket joint is connected, the extruded adhesive should be wiped clean with yarn or a dry cloth dipped in a little acetone or other cleaning agent. Wait until the interface is cured according to the performance of the adhesive and the climatic conditions. The curing time should be appropriately extended during winter construction.