Location: Home/

Jingyuan Plastic Industry/

Products/

Polyvinyl chloride resin

Location: Home/

Jingyuan Plastic Industry/

Products/

Polyvinyl chloride resin

Polyvinyl chloride is a high-molecular compound polymerized from vinyl chloride monomer (VCM), with its structural unit (-CH2-CHCI-)n, where n represents the degree of polymerization, typically ranging from 590 to 1500. During the re-polymerization process, due to the influence of various factors such as polymerization technology, reaction conditions, reactant composition, and additives, eight different types of polyvinyl chloride resins can be produced, and thus the performance of each resin varies. According to the amount of vinyl chloride contained in polyvinyl chloride resin, it can be classified into three types: industrial grade, food grade and hygiene grade. The appearance of polyvinyl chloride resin: It is a white powder or white granular substance, with an average density of 1.40g/cm ³

Category: Polyvinyl chloride resin

Key words: Polyvinyl chloride resin, chlorinated polyethylene, polypropylene, ABS

Polyvinyl chloride is a high-molecular compound polymerized from vinyl chloride monomer (VCM), with its structural unit (-CH2-CHCI-)n, where n represents the degree of polymerization, typically ranging from 590 to 1500. During the re-polymerization process, due to the influence of various factors such as polymerization technology, reaction conditions, reactant composition, and additives, eight different types of polyvinyl chloride resins can be produced, and thus the properties of each resin vary. According to the amount of vinyl chloride contained in polyvinyl chloride resin, it can be classified into three types: industrial grade, food grade and hygiene grade. The appearance of polyvinyl chloride resin: It is a white powder or white granular substance, with an average density of 1.40g/cm².

Product application

Polyvinyl chloride resin is a general-purpose synthetic resin with a wide range of applications. It can be used in the production and processing of polyvinyl chloride hard products, soft products, coatings and adhesives. By application field on schedule:

1.Building materials: such as pipes, plates, doors and Windows, etc.

2. Packaging materials.

3. Electronic equipment: such as wires, cables, tapes, pins, etc.

4. Furniture and decorative materials.

5. Others: such as automotive materials, medical devices, etc.

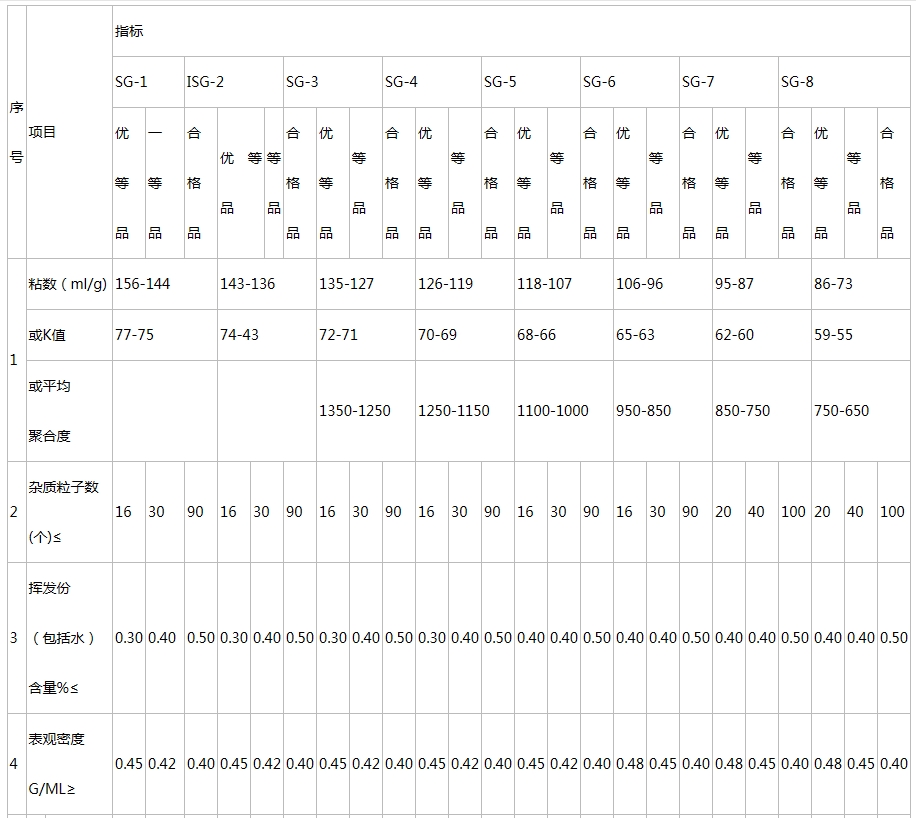

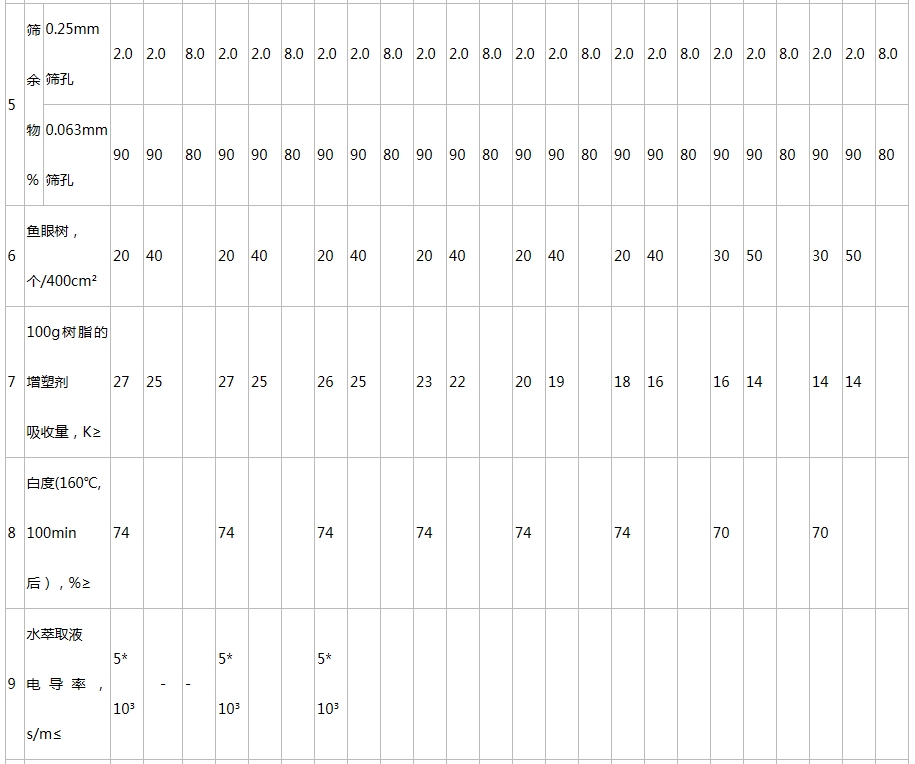

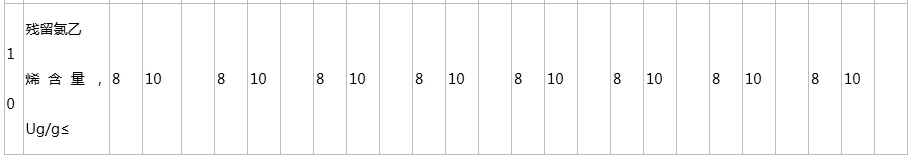

Characteristics and quality standards

1. Common type polyvinyl chloride resin

This product is a white amorphous powder with a specific gravity of 1.35-1.46(at 20℃). It is insoluble in water, alcohol and gasoline, but can expand and dissolve in ethers, ketones, chlorinated fats and hydrocarbons, acetone, cycloethyl ketone and aromatic hydrocarbons.

2. Cold-resistant polyvinyl chloride resin

Cold-resistant resin is a white amorphous powder. This copolymer features internal plasticization, cold resistance, good transparency, and electrical properties. It is a new type of modified polyvinyl chloride resin. Besides the common characteristics of polyvinyl chloride resin, it has excellent low-temperature performance. After molding and processing, polyvinyl chloride plastic products are soft, not brittle, not broken, and have a good hand feel.

3. Polyvinyl chloride resin for food use

This product is a white amorphous powder. The residual amount of polyvinyl chloride in the resin is ≤5ppm. Other properties are the same as those of ordinary polyvinyl chloride resin.

Specification requirements for polyvinyl chloride resin

Packaging and storage

Store in a cool, dry and well-ventilated warehouse in a polyvinyl chloride film bag with an outer polypropylene woven bag of SG type, each bag weighing 25kg.