Location: Home/

Jingyuan Plastic Industry/

Products/

Chlorinated polyethylene

Location: Home/

Jingyuan Plastic Industry/

Products/

Chlorinated polyethylene

CPE is the abbreviation of chlorinatedpolyethylene, which is the product of chlorination of high-density chlorinatedpolyethylene. It appears as fine white particles. The performance of CPE: 1. Excellent aging resistance, capable of being used in harsh climates and demanding environments, and has sufficient resistance to ozone. 2. Excellent flame retardancy and no self-ignition. 3. It has excellent low-temperature toughness and can maintain flexibility at -201, making it suitable as an impact modifier for UPVC products. 4. Excellent chemical resistance, showing inertness to most chemicals and resisting various types

Category: Chlorinated polyethylene

Key words: Polyvinyl chloride resin, chlorinated polyethylene, polypropylene, ABS

CPE is the abbreviation of chlorinated polyethylene, which is the product of chlorination of high-density chlorinated polyethylene. It appears as fine white particles.

The performance of CPE

It has excellent aging resistance and can be used in harsh climates and demanding environments. It also has sufficient resistance to ozone.

2. Excellent flame retardancy and no self-ignition.

3. It has excellent low-temperature toughness and can maintain flexibility at -201, making it suitable as an impact modifier for UPVC products.

4. Excellent chemical resistance, showing inertness to most chemicals and resisting corrosion by various acids and alkalis.

5. Good processing performance and easy to be processed into shape.

6. Excellent safety in use, without causing any adverse effects on the human body or the surrounding environment.

7. Excellent stability.

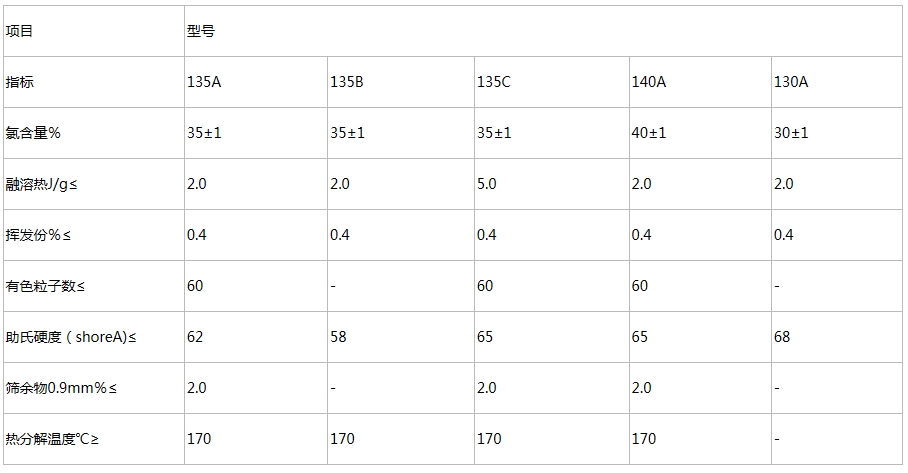

Quality indicators

The main uses of CPE

CPE possesses the dual properties of both plastic and rubber, and has good compatibility with other plastics and rubbers. Therefore, except for a few used as the main material, CPE is mostly used in combination with rubber or plastic. When CPE is used in combination with plastics, it is mainly used as a modifier. Its primary application is as an impact modifier for rigid polyvinyl chloride (UPVC) products, improving the impact resistance and low-temperature performance of UPVC. It can be used to manufacture UPVC window and door profiles, pipes, and injection molded products, etc. When used in combination with rubber, CPE mainly improves the flame retardancy, insulation, aging resistance and other properties of rubber. In addition, CPE135C can be used as a modifier for flame-retardant ABS resin and also as an impact modifier for injection of PVC, PC and PE.